According to the guidance for the Fire Safety Order, signs must comply with BS5499-4 and 5 as well as the Safety Signs and Signals Regulations.

Good Practices in Occupational Risk Management

Introduction

Occupational risk management is part of occupational health and safety in the workplace.

The use of risk management strategies has increased among businesses, especially those with larger enterprise and occupational safety and health (OSH) departments. However, this approach may be less common among smaller organizations

Managers must understand their legal and moral responsibility for ensuring a healthy and safe workplace, and they must make every effort to achieve and maintain this goal.

Risk management is the process by which management assesses risks, determines control measures, and takes appropriate actions to reduce those risks.

What is Occupational Risk Management?

It is a systematic approach to managing workplace hazards. It is a critical component of any organizational management that identifies, evaluates, and determines the means of reducing risks to an acceptable level in order to protect employees, visitors, contractors, and other individuals at the workplace.

Risk Management Vs. Risk Assessment

Risk assessment is the process of identifying workplace safety and health hazards, assessing the level of risks involved, and setting priorities for controlling the hazards and lowering the risks.

Risk management, like risk assessment, involves assessing the risks associated with any work activity or trade. However, it also includes risk control and monitoring, as well as risk communication.

Why Occupational Risk Management is Important?

Risk management is an essential component of any business, and a lack of risk management can result in work-related injuries, occupational diseases, or deaths in an organization or workplace.

Risk Communication in Occupational Risk Management

Good risk communication is essential for two reasons:

Risk managers, or those who make decisions related to risk management, must be aware of the potential risks and benefits of each possible course of action.

The scientists who have assessed the risks and benefits must convey this information to them.

When risk management decisions are made at a societal level, people who will be affected need to know the reasoning behind the decisions and have an opportunity to contribute to the decision-making process (e.g., through consultation processes or lobbying of politicians).

It is difficult to convey a clear assessment of risk, especially when the target audience is not scientifically trained.

The language used should be suitable for the target audience, and making comparisons to more well-known risks may be helpful (e.g., how risk compares with that of a road traffic accident or from living with a smoker).

6 Governmental Strategies for Occupational Risk Management

Governments have a variety of options for risk management, including the following strategies: –

- Outright bans.

- Regulations requiring effective control technology.

- Setting a standard to limit exposure.

- Public health advisory messages.

- Public education.

- Impose fines, taxes, or penalties for unsafe use.

7 Industrial Strategies for Occupational Risk Management

There are numerous ways for industries to deal with hazards, including the following:

- Control technology.

- containing or isolating the hazard.

- Using a less hazardous product in the production process.

- Administrative controls to track and limit worker exposure.

- Educating employees

- Providing personal protective equipment.

- Good housekeeping.

7 Steps Involved in Occupational Risk Management Processes

To prevent disease and injury, risk management is essential. It contains:

- Spotting the hazards.

- Assessing the risks.

- Implementing the necessary changes to eliminate the hazard or reduce the risk of injury or harm to health.

There are seven essential steps in the risk management process, which will be covered in more detail.

STEP 1 Planning

- Identifying who participates in the risk management process.

- gathering relevant health and safety information.

- Understanding the legal requirements.

- Identifying and understanding the risk criteria, i.e., the acceptable safety standards in both the mining industry and your workplace.

The Team

The risk assessment team should include management, supervisors, and employees who may be exposed to the hazard.

This could mean that team members may change several times throughout the workplace, depending on the area and activity being assessed.

The team should also include safety and health personnel, safety and health representatives, and, if necessary, specialists.

Gathering Information

All relevant information should be accessible to the team, including: –

- Legislative requirements

- Standards for national and industry safety and health.

- Department of Minerals and Energy safety and health information, such as Significant Incident Reports, Safety Bulletins, Codes of Practice, Guidelines, and so on.

- The risk criteria of the company.

- Safe working procedures.

- Safety data sheets for materials.

- Mine plans, floor plans (old and new).

- Data on accidents and incidents, including accident investigation reports.

- Inspection reports.

- Audit reports.

Risk Criteria

To assess the risks, the team must first understand the context in which a hazard can be controlled.

The goal is to eliminate the risk, but this is not always possible.

Risk criteria are agreed upon at the commencement of the process.

Risk criteria set the “acceptable” level of risk that will be used to assess each risk.

The criteria enable the team to determine what should be done to control the risk.

Before identifying hazards and assessing risk, the team must agree on an “acceptable level of risk” for that workplace, which becomes the “risk criteria” against which risks are assessed.

The team will take into account operational, technical, and/or legal requirements, local community sensitivities, and public perception when determining its risk criteria.

For example, a risk may be considered low after analysis, but due to public perception, legal requirements, or other factors, it may be increased to a high priority for that workplace.

The analysis will enable the team to assess the risks in comparison to the agreed risk criteria, which is against the acceptable level of risk.

The team will need to make some judgments on the potential likelihood and consequences of each hazard, such as fatal injury or serious injury, and have an understanding of the means and cost of controlling the associated risk.

STEP 2 Hazard Identification

Identifying every hazard that has the potential to harm or injure a person is necessary, regardless of how minor the hazard may be.

The assessment team must identify the following for each hazard:

- What could happen?

- How and why, it could happen?

To answer these questions, the team should review the relevant information obtained during Step 1 Planning and carry out a workplace inspection to address what is happening:

- Observe actual practice rather than procedures or job instructions.

- Consider non-routine operations such as breakdown and scheduled maintenance.

- Pay attention to interruptions and changes.

The team should create a comprehensive list of potential hazards or events that could affect the work activity.

If the workplace is divided into sections and inspected separately, this might be simpler.

A checklist can help to make sure that all hazards are identified and documented.

During the inspection, the team should observe the actual tasks and speak with the employees who work in the area to obtain their views on the nature of the risks involved.

All hazards may not be noticeable during the inspection period, and it may be necessary to return when specific tasks are being carried out.

Examples of Hazards

- Handling of flammable liquids when there are ignition sources present.

- An unlabeled container of caustic soda that, if handled incorrectly, has the potential to cause severe skin burns.

- Motor vehicles driving or other powered equipment on site.

- Loose asbestos that was released during demolition.

- Uninsulated chainsaw noise, which can be as loud as 110 dB and potentially cause serious hearing damage.

- A shovel that is poorly designed (for example, with a short handle and a very large blade) has the potential to cause back injury.

- Waste engine oil could lead to slips and falls or harm workers’ health through skin absorption.

- Blood in a syringe at a hospital could infect a worker if the needle punctures the worker’s skin.

STEP 3 Risk Identification

Examples of risk identification

Hazard → Frayed wires on electrical items.

Risk → Operator may be electrocuted.

Hazard → Unguarded rollers on the printing machine.

Risk → Operator’s hand may be drawn in and crushed.

Once a hazard to health and safety has been identified, the risk associated with that hazard must be examined. It is helpful to identify factors that might be causing the risk.

Understanding the risk associated with the hazard in question will be easily achieved by reviewing current health and safety information, such as local workplace accident records and/or information about the hazard or risk that is available from national or other jurisdiction authoritative sources.

STEP 4 Risk Analysis and Risk Assessment

Risk Analysis

The team creates a risk analysis using the list of hazards by identifying potential consequences and their likelihood of occurring.

This will make it easier to assess the likelihood of an event happening and the potential exposure.

It is essential to take into account all potential causes because there are various ways that an exposure or event can initiate.

Include all persons who may be affected in the analysis, such as visitors or contractors.

Highlight the groups or individuals who are most at risk, and objectively assess the effectiveness of the current control measures.

To analyze risk, the team must consider both the possibility of the hazardous situation occurring and the extent of the harm that would result.

The team must determine the following for each hazard:

- How are individuals exposed?

- probabilities of exposure.

- Exposure frequency (when and how often), such as intermittent (decanting a hazardous substance) or continuous (noise).

- Exposure-related consequences, such as lost production time, fatality, severe injury or permanent health impairment, machinery damage, minor injury, or reversible health effect.

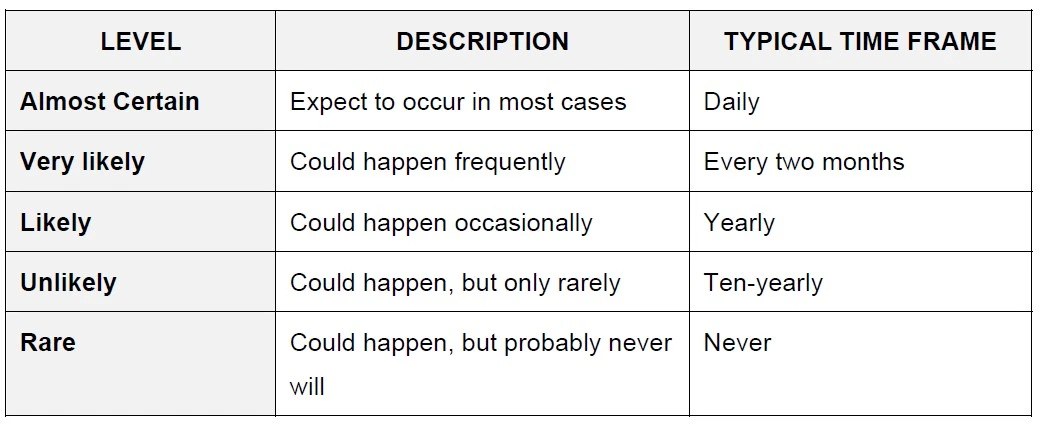

Likelihood can be rated as:

The consequence, about injury, can be rated as:

Fatal Injury → Sudden death, or death after prolonged disease.

Serious injuries → Normally irreversible injuries, or serious health impairment.

Minor injuries → Normally reversible injury, or damage to health needing several days off work.

First Aid Injuries → Normally very minor injuries that will not require time off work.

In the majority of situations, it might be necessary to perform a preliminary analysis first, followed by a more in-depth analysis later.

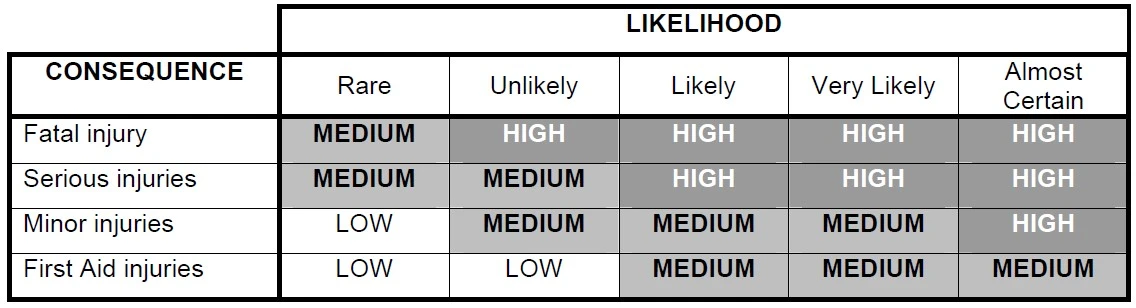

The likelihood and consequence are then compared to determine the severity of the risk.

The most serious (HIGH risk) consequences are those that are “very likely with fatal consequences,” while the least serious ones are “highly unlikely with first aid injuries” (LOW risk).

Risk Assessment

Risk assessment involves comparing the risk level identified during the risk analysis process to previously established risk criteria and ranking the risks in order of severity.

The team’s goal is to evaluate all of the risks that each hazard presents to control it.

After the risks have been assessed and ranked, the action to remove or reduce the risk should be determined and prioritized based on the risk value.

STEP 5 Risk Control

Risk control and risk reduction include identifying and implementing various strategies for dealing with risks that do not meet the acceptable risk criteria.

Risks should be kept as minimal as reasonably possible, regardless of any absolute criteria.

Technological advancements should be considered when controlling risks.

The risk associated with a particular hazard can never be completely eliminated unless that hazard is removed.

Avoiding a risk entirely is always preferable.

Whenever possible, work should be tailored to the individual rather than the individual being tailored to the work, and risk should be eliminated at the source rather than using secondary measures.

Measures that reduce high-level risks should be given top priority.

Low-level risks may be acceptable with minimal additional treatment, but they should be monitored and reviewed regularly to ensure they remain acceptable.

Measures to avoid, prevent, and reduce risk must be an accepted part of the organization’s culture at all levels.

Employees need to be aware of what they must do to make sure the controls are effective.

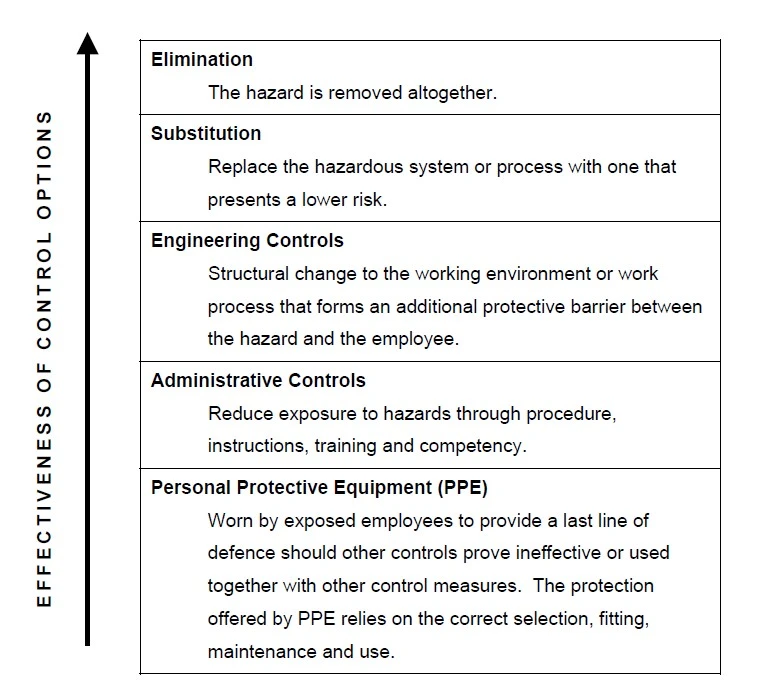

The Hierarchy of Control is a term used to describe risk control and reduction techniques. Often, more than one method of control is required to meet the risk criteria.

The hierarchy of control methods include:

In some cases, where the risk of exposure is highly unacceptable, immediate action may be required to control the exposure before long-term control, or more permanent or more expensive, measures can be introduced.

Employees, for example, may be required to wear respiratory protection to control exposure to a hazardous substance in the short term until more effective local exhaust ventilation can be installed.

Reasonably Practicable

What is known about an individual hazard, its associated risks, and the severity of potential injury or harm to health is evaluated against the overall cost and feasibility of the control measures required to eliminate or reduce the risk.

Selecting the appropriate level of control will require a judgment on what is “reasonably practicable”.

The team needs to determine:

- How serious are the hazard and its associated risks?

- What is known about it, and how is it controlled?

- Whether the means to control the risk are available.

- Whether the benefit will justify the cost.

When determining whether a control measure is reasonably practicable, the team must consider what is common practice and knowledge in the industry.

It is unacceptable for an employer to claim that they do not know what to do about certain hazards if those hazards are widely known by others in the industry and safeguards are in place.

STEP 6 Documenting the Process

Documenting the process will help ensure that the identified control measures are implemented as intended.

It will also help in the management of other hazards and risks that may be similar to those already identified and dealt with.

Adequate record keeping of the risk management process will also help in proving to the regulator—or in litigation—that you have been actively working to ensure safety at your workplace.

Records should demonstrate that the process was carried out correctly, including information about the hazards, associated risks, and control measures that were implemented.

Information should include:

- Identification of Hazards

- Risk assessments associated with those hazards.

- Decisions on control measures to manage exposure to the risks.

- when and how the control measures are implemented.

- Evidence of monitoring and review of the effectiveness of the controls.

- Any checklist that was used during the process.

STEP 7 Monitoring and Review

Establishing a monitoring and review program is necessary to guarantee that the control measures are still effective, i.e., that they control the risk of exposure within acceptable limits.

Hazards and risks must be monitored to ensure that changing conditions do not alter the effectiveness of control measures.

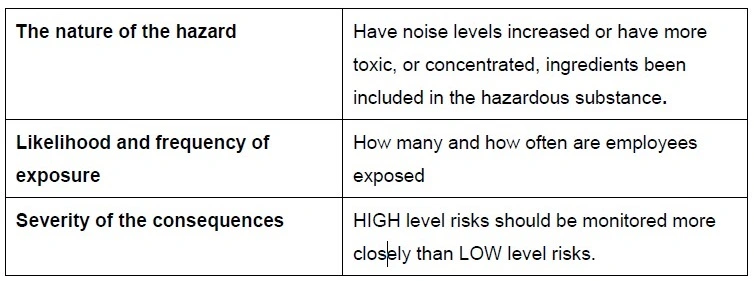

The monitoring program should be developed to review changes to the:

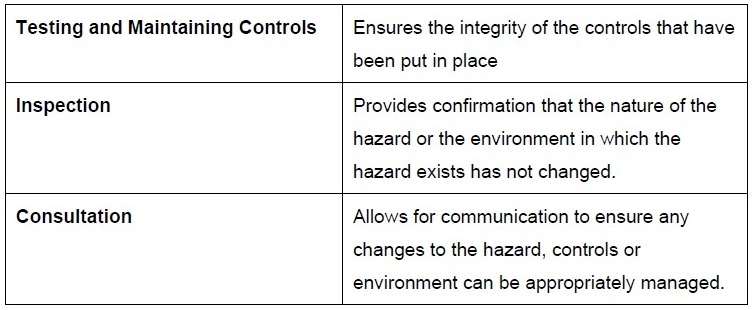

These programs include:

Any changes to the process or work activity, including changes in the employees performing the task, should initiate a review of the assessment.

Follow-up inspections and reviews should be adequately documented, and training should be identified as needed.

Summary

Occupational risk management is part of occupational health and safety in the workplace.

The use of risk management strategies has increased among businesses, especially those with larger enterprise and occupational safety and health (OSH) departments. However, this approach may be less common among smaller organizations

Risk management is the process by which management assesses risks, determines control measures, and takes appropriate actions to reduce those risks.

Occupational Risk Management is a systematic approach to managing workplace hazards. It is a critical component of any organizational management that identifies, evaluates, and determines the means of reducing risks to an acceptable level to protect employees, visitors, contractors, and other individuals at the workplace.

To prevent disease and injury, risk management is essential. It contains:

- Spotting the hazards.

- Assessing the risks.

- Implementing the necessary changes to eliminate the hazard or reduce the risk of injury or harm to health.

There are seven essential steps in the risk management process, which will be covered in more detail.

STEP 1 Planning

- Identifying who participates in the risk management process.

- gathering relevant health and safety information.

- Understanding the legal requirements.

- Identifying and understanding the risk criteria, i.e., the acceptable safety standards in both the mining industry and your workplace.

STEP 2 Hazard Identification

Identifying every hazard that has the potential to harm or injure a person is necessary, regardless of how minor the hazard may be.

The assessment team must identify the following for each hazard:

- What could happen?

- How and why, it could happen?

STEP 3 Risk Identification

Examples of risk identification

Hazard → Frayed wires on electrical items.

Risk → Operator may be electrocuted.

Hazard → Unguarded rollers on the printing machine.

Risk → Operator’s hand may be drawn in and crushed.

Once a hazard to health and safety has been identified, the risk associated with that hazard must be examined. It is helpful to identify factors that might be causing the risk.

STEP 4 Risk Analysis and Risk Assessment

The team creates a risk analysis using the list of hazards by identifying potential consequences and their likelihood of occurring.

This will make it easier to assess the likelihood of an event happening and the potential exposure.

It is essential to take into account all potential causes because there are various ways that an exposure or event can initiate.

Risk assessment involves comparing the risk level identified during the risk analysis process to previously established risk criteria and ranking the risks in order of severity.

The team’s goal is to evaluate all of the risks that each hazard presents to control it.

STEP 5 Risk Control

Risk control and risk reduction include identifying and implementing various strategies for dealing with risks that do not meet the acceptable risk criteria.

Risks should be kept as minimal as reasonably possible, regardless of any absolute criteria.

STEP 6 Documenting the Process

Documenting the process will help ensure that the identified control measures are implemented as intended.

It will also help in the management of other hazards and risks that may be similar to those already identified and dealt with.

STEP 7 Monitoring and Review

Establishing a monitoring and review program is necessary to guarantee that the control measures are still effective, i.e., that they control the risk of exposure within acceptable limits.

Hazards and risks must be monitored to ensure that changing conditions do not alter the effectiveness of control measures.

How useful was this post?

Click on a star to rate it!

Average rating 0 / 5. Vote count: 0

No votes so far! Be the first to rate this post.

I'm sorry that this post was not useful for you!

Let me improve this post!

Tell me how I can improve this post?

References

Workplace Safety and Health (Risk Management) regulations. (n.d.). Retrieved January 10, 2023, from Ministry of Manpower

Occupational Risk Management in industry – university of galați. Retrieved January 10, 2023, from University of Galati

Guidotti, T. L. (2011). Global Occupational Health. Oxford University Press.

Sadhra, S. S., Bray, A., & Boorman, S. (2022). Oxford Handbook of Occupational Health. Oxford University Press.

GUIDELINES ON OCCUPATIONAL SAFETY AND HEALTH (OSH) RISK MANAGEMENT FOR SMALL AND MEDIUM ENTERPRISES IN ASEAN MEMBER STATES. (n.d.). Retrieved January 11, 2023, from Association of Southeast Asian Nations

Safety and Health Risk Management – gold mining in Western Australia. (n.d.). Retrieved January 11, 2023, from Department of Mines and Petroleum

Guide six steps to risk management – worksafe.nt.gov.au. (n.d.). Retrieved January 11, 2023, from NT WorkSafe

(PDF) Occupational Risk Management in industry – researchgate. Retrieved January 11, 2023, from ResearchGate

Silicosis is a type of pneumoconiosis caused by the inhalation and deposition of dust containing crystalline silicon dioxide, typically in its most common form, which...

Organic Dust Toxic Syndrome (ODTS) | Symptoms, and Treatments

Organic Dust Toxic Syndrome (ODTS) is an acute inflammatory condition of the lower respiratory tract. It is a flu-like illness caused by respiratory exposure to...

Byssinosis is a chronic nonspecific respiratory disease that affects textile workers who are exposed to the dust of cotton, flax, hemp, jute, and sisal.

Featured Posts

Recent Posts

Popular Posts

Learn More